Resin and color specifications

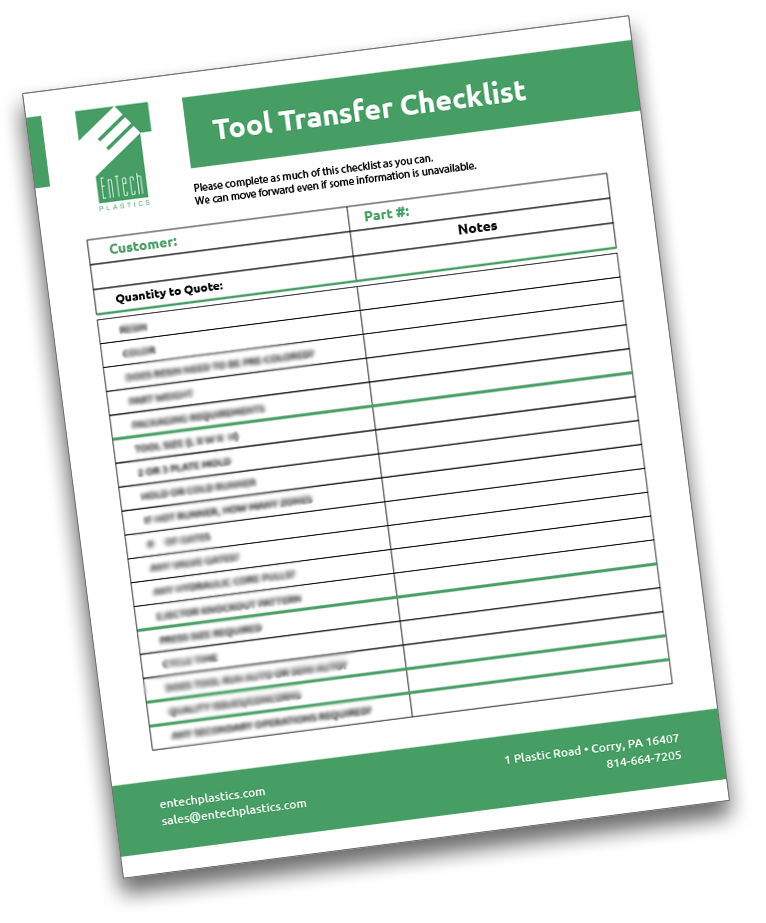

Ensure a Smooth Tool Transfer with Our Comprehensive Checklist

Transferring injection molding tools doesn’t have to be stressful. Get the proven framework that protects your production continuity and part quality.

Download Your Free Checklist

Complete the form below to get instant access to the Tool Transfer Checklist.

Why You Need This Checklist

Minimize Disruption

Systematic planning ensures you maintain production continuity throughout the transfer process.

Protect Part Quality

Document critical specifications upfront to ensure consistent quality at the new facility.

Reduce Transfer Risks

Address mold compatibility, process parameters, and auxiliary systems before issues arise.

Save Time and Money

Avoid costly delays and quality issues by having all essential information organized from day one.

Don’t leave your tool transfer to chance.

This checklist covers everything from resin specifications and mold dimensions to cycle times and secondary operations—ensuring nothing gets overlooked.

What’s Inside

Want to learn more about tool transfer best practices?

Read our in-depth guide: How to Minimize the Challenges of Transferring an Injection Molding Tool to a Different Supplier